Category Archives: Blog Post

Remembering Why We Do Flame Hardening This Way

How many times have you caught yourself doing something a certain way and then wondering why you always do it that way? And realizing that reason no longer exists! For example, why

“The Perfect Couple”

I received a call recently from a customer who had come to us to solve his heat-treating problems nineteen years ago. Back then he had started out producing anvils (yes, blacksmithing anvils).

“How Much Do Flame Hardening Machine Cost?”

One reason I love the Internet is that it’s given people all over the world a chance to send us flame hardening orders and questions. I love getting a request for flame

Small Companies, Big Ideas

Here’s a fascinating story of evolution in which flame hardening solved the main problem – bringing his heat treating inhouse in a way to increase profits – so he could then have the money

The Heat-Treating Industry Loses Another Good One.

Mervin M. Sirrine Obituary Mervin Mitchell Sirrine, 87, of Bellaire, formerly of Midland, died Wednesday, June 20, 2018 at Brittany Manor. He was born Oct. 30, 1930 in Midland, son of

Heat Treating Hacks On Being Hacked

“Fake News” and cyber-hacking are in the news constantly these days. What does THAT have to do with heat-treating, you ask? Well, heat-treating is a business and you cannot do business today

How to Create a Good Enough Flame Hardening Process

It’s no secret that globalization has introduced tremendous pressures in manufacturing to produce more, faster, and for a lower price. Recently as I’ve gone out consulting at customer plants in the mid-Atlantic

Flame Hardening; How do you know the best way?

When you’re the one tasked with figuring out the best flame hardening solution for your manufacturing process, how do you know the best way to spend that time and money? What’s going

Flame Hardening and Manufacturing’s Labor Shortage

Men and machines. That’s been the story of the Industrial Revolution for the past 120 years. It’s the story of flame hardening as engineers have continued to build upon a timeless process

Coming In From The Cold

Here in North Carolina, the winter has been exactly as the National Weather Service predicted: warm and dry, a typical result of the La Nina weather pattern in the Pacific. This morning

Just Throw Some Heat At It

Since a blog is usually some way for the author to try and educate readers about some topic, let’s start the New Year with busting some widely held misconceptions about heat treating

How to Get the Most Out of Outsourcing Your Flame Hardening

Now that we’re providing more and more flame hardening services for customers, I wanted to share with you some things we’ve learned that could be helpful if you’re considering paying a heat

Basics of Successful Flame Hardening

Our customers must be seeing a rebound in the heavy manufacturing sector in Q4, because our phone has been ringing off the hook. We love hearing from customers that are using our

Temper, Temper!

Blog post by Mark Sirrine with metallurgical help from Jim Senne of MetalPro Resources Part of what makes our work so interesting – and sometimes, so frustrating – is that heat treating

When Can You Upgrade Equipment Instead?

Last month our blog explored issues related to the challenges of moving forward on the capital expense for a new flame hardening machine – a complete set-up customized to handle the parts

Why Buy a Flame Hardening Machine?

I’ve been working with a lot of folks lately trying to decide whether there is a business case for buying their own flame hardening machines, so I thought this might be a

Pay Me Now or Pay Me Later

This month I have to admit a change of heart regarding the servicing of flame heads. Since typical flame heads cost on average $1500-3000, with some going as high as $15,000, I feel compelled to advise

Lions & Tigers & Flames, Oh My!

I recently had a conversation with someone who was describing some upgrades to her church’s kitchen. The gas range was replaced with an electric one, she said. Since I’ve always heard that

Coming Up for Air

In our last blog post, we talked about the art of choosing and using the proper fuel gas for your application. Flame hardening allows for different types of fuel gas to be

Picking the Right Fuel Gas for Flame Hardening

As the world’s premier manufacturer of flame hardening systems, we know that product installation and support remain at the top of our customers’ priority lists. We also know that our customers are

It’s Not Just the Heat, it’s the Cool – Part 2.

We ended the last blog talking about examples of quench severity applications to particular parts during the flame hardening process with flame hardening equipment. Examples like a gear with small teeth: it

It’s Not Just the Heat, it’s the Cool.

We say that around here to remind us and our customers that the terms “heat treating” and “flame hardening” only tell half the story. Heating metal seems to hog all the glamor,

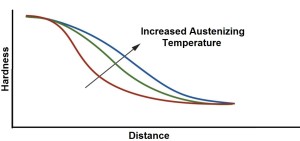

Reaching Max Austenizing Temperature

How do you know when a part reaches its maximized Austenizing temperature? That’s the knowledge separating the flame hardening pros from the amateurs. The length of the heat cycle is affected by

Going with the Flow in Flame Head Design

This week we continue the topic of flame head design and its importance to successful flame hardening. The shape of the design not only impacts how the part will be hardened, but

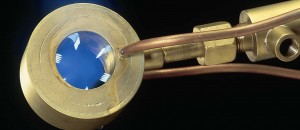

It All Starts with Flame Head Design

Flame heads are to flame hardening as coils are to induction. They are the most critical component of successful flame hardening equipment, both in the design and in the careful maintenance to

Happy Thanksgiving

This week we’d like to recognize our national Thanksgiving holiday by giving a special shout-out to all of the employees, customers, vendors, and friends who’ve journeyed with us over the past forty-plus

Time to Re-tool and Revamp Your Flame Hardening Equipment?

Now that all our flame hardening display items have been shipped back and put away until 2017, we at FTSI have put our heads together on what we learned during our stay in Detroit

Combining the Best of Both Worlds

So far we’ve covered applications for progressive flame hardening machines and spin hardening machines (The Beauty Of Spin Hardening) . It’s possible to combine these two methods when hardening cylindrically shaped parts that need

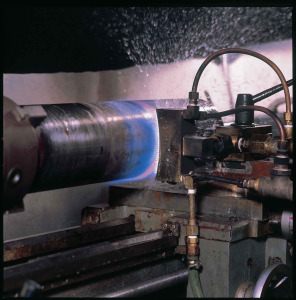

Progressive Applications of Flame and Quench

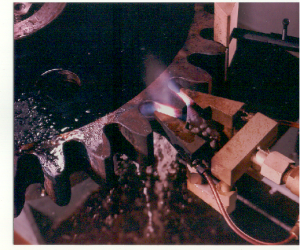

This week we’re looking at the progressive flame hardening method. Progressive flame hardening features a specially designed flame head that includes both flame and quench. Heating and cooling both occur as the

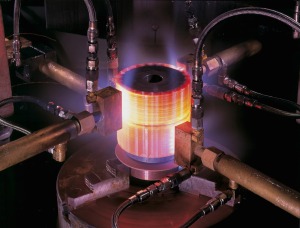

The Beauty of Spin Hardening

Let’s review flame hardening equipment and design methods. All localized hardening methods (induction, flame) consist of heat and quench. In stationary flame hardening, the part and/or flame head remains in place for

Heat Treat Show Heats Up!

Believe it or not, it was warmer this morning in Detroit than back down in Raleigh! That makes sense, because the heat is on for the ASM International Heat Treat show. Yes,

ASM Heat Treat Show 2015 – Come See Us, Booth #722

We interrupt our regularly scheduled blog post to talk about next week’s ASM Heat Treat Show and Gear Expo at the Cobo Center, Detroit Michigan. Yes, Detroit. I used to live there

Flame Hardening Methods and Applications

As we continue to discuss heat treating design issues, let’s do an overview of four distinct flame hardening methods we use at FTSI to meet various client needs. These flame hardening methods

Tips for Getting Quality Outsourced Flame Hardening Solution

Last week we covered the highlights of designing an inhouse flame hardening solution; this week we’ll talk in more detail about the other choice – outsourcing. The most compelling reason clients have

Flame Hardening In-House; Two Major Considerations

This week, let’s talk shop – what to consider when deciding to do flame hardening on your shop floor. In design, there are two major considerations: engineering and budget estimate. When customers

How To Choose The Best Heat Treating Solution.

Unless your production line already has been using a specific type of heat treating, your design solution will have to analyze which of the three typical heat treating processes best fit your

Pros And Cons Of Heat Treating Inhouse Or Outsourcing With A Specialized Facility

Because of our 21st-century globalized manufacturing economy, most customers want to know whether it makes more financial and quality sense to do heat treating inhouse, or whether the best solution is to

Deeper Look At Materials Handling And Facilities

This week we finish up our introduction to the basic questions you need to answer when designing your heat treating solution. Once you have your material, your hardness level, and the geometric

Cost Analyses Of Flame Hardening Component For Your Production Line

Once you know you need to harden a piece of steel or cast iron, how do you go about designing the right application for your needs? There’s a lot of ways to

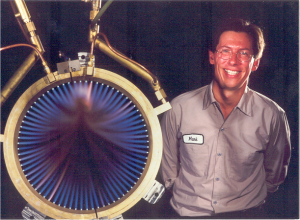

Mark Sirrine; The Spinning Machine, Spin Hardening Parts

We’re here to answer any questions you have. Call Flame Treating Systems, Inc office at (919)956-5208 or email me personally, mark@flametreatingsystems.com. I look forward to speaking with you.

Safety and Flame Hardening, Part 2

Understandably, some clients are nervous about using fuel gas and oxygen to create flame. You simply have to design flame hardening equipment to mitigate the risks associated with them. Ignition and shutoff

Safety and Flame Hardening (Part 1)

This blog starts a series of posts that will delve more deeply into the flame hardening process itself. We begin this week with safety concerns and then end up with design tips

Hardness pattern problems

This week we’re getting into more refined problems related to heat treating – namely, uneven hardness patterns and a hardness pattern that doesn’t go deep enough to meet spec. We see these problems

Goldilocks Knows Her Heat Treating… “Just Right”

Heat treating metals all involve getting it “not too hot, not too cold, but just right” for the resulting hardness level to meet specifications. Although it may appear like trial and error

Successful Heat Treating; Understanding of Materials Composition.

This week we tackle issues more commonly encountered as part of the debugging and startup phase of installing a new flame hardening process. As with any new process, flame hardening requires some

Surface Burning Can Result From A Number Of Factors. We Can Solve.

This week continues our discussion of heat treating problems and how to solve them. What we call “surface burning” actually describes the melting of a part’s surface. Obviously this is something you

The Real Question Is Determining Your Tolerance For Distortion.

This week I’m going to discuss the problem of distortion. Well, it’s only a problem when the distortion is considered excessive – when the heat or cooling cycles of the process distort

Cracking The Heat/Quench Cycle

Having been around the block a few times, we at FTSI have seen all sorts of quality problems with various customer’s existing heat treating solutions, which we are then asked to solve.

The Secret Sauce of Heat Treating

Why would anybody write a blog about heat treating? I mean, it’s just a means to an end. What you really want is a production line that’s producing parts according to hardness

Flame – Hardening Crane Wheels

The spinning flame-hardening method is an ideal way to harden a steel or cast iron crane wheel. See how it’s done with this video: The crane wheel in this video is 1045