Gear Flame Hardening

Gear Flame Hardening; Hardening of Steel And Hardening of Cast Iron

The hardening of steel gears and cast iron gears is achieved using several different methods and techniques including flame or induction hardening, carburizing and nitriding. Since what we do is flame hardening and flame hardening is a time- tested method for hardening metals, this is what we’ll concentrate on.

There are two main techniques used for the flame hardening of steel gears: spin heat / drop quench and tooth-at-a-time.

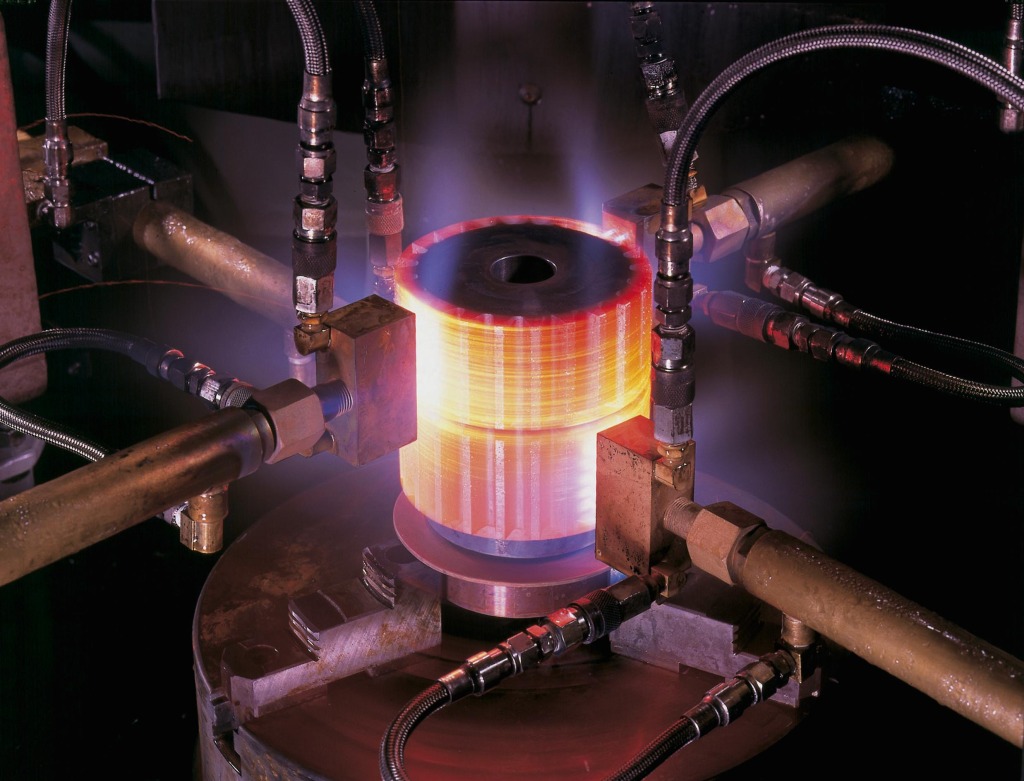

Spin Method

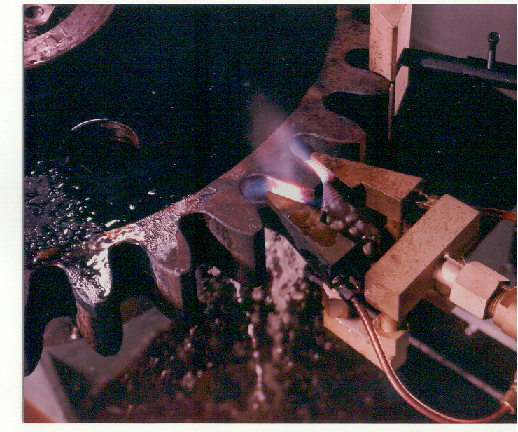

Tooth-at-a-Time Method

The spin flame hardening will typically create hardness through the tooth and depending on pitch will harden below the root. Some metal growth and distortion will occur. The amount of growth and distortion will depend on how much heat is applied to the gear. This method works great for higher production situations because the cycle time is relatively short.

The tooth-at-a-time method incorporates two different techniques for hardening the tooth, depending on where you want the hardness to be and the size of the pitch of the gear. A flank pattern hardens only the sides of the tooth and is achieved using special progressive water quench flame heads that scan, first heating then quenching the tooth face (See Tooth-at a Time Method photo above). If the gear pitch is large enough, flame heads can be designed that harden both the flank and the root, and this same progressive method can be used. For smaller gear pitches the second technique is to first heat the root and flank then spray quench.

The tooth-at-a-time method will have less metal growth and distortion than the spin heat method. But this method will take longer to process a gear than the spin heat method. Multiple flame and quench stations can be set up in order to speed up the processing.

In order for all these processes to work properly, a complete flame hardening system is required. The proper flame head design, plc controls of scanning speeds and heat times, control and monitoring of oxygen and fuel flows are critical for the proper flame hardening of steel gears.

For over 40 years, Flame Treating Systems, Inc. has been designing and building a broad range of heat treating equipment: complete systems as well as specialized components to be used in heat treating machinery.

If you have questions about your heat treating solution, email me at mark@flametreatingsystems.com or call 919-956-5208.