Rexnord Corporation – Case Study

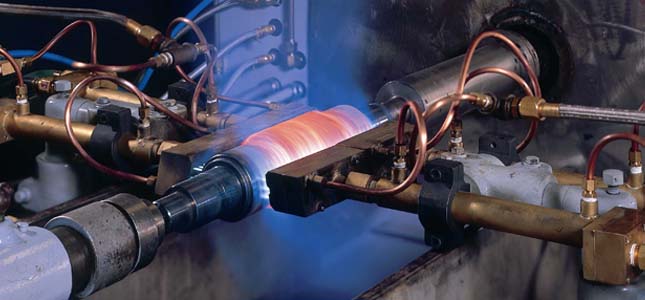

Rexnord Corporation (Horsham, PA), manufactures industrial power transmission products. The firm used a Cincinnati Flamatic flame hardening system to harden worm gears for speed reducers. When production of the Flamatic units was discontinued and spare parts became increasingly difficult to locate, Flame Treating Systems was contacted to upgrade the equipment.

In its overhaul of the Flamatic system, FTSI added an optical pyrometer, flow meters, electronic ignition and computer-based electronic controller. Operation of the unit involves rotating AISI 4150 steel parts between flame heads at 30 RPM before quenching them in a water-based polymer to produce desired hardness specs of 56 to 62 HRC. The specs vary from part to part, according to the gear being treated. The size of the gear and the hardness spec dictate the number of flame heads used in any particular system configuration (up to four, maximum).

The optical pyrometer is calibrated to measure temperatures between 600° and 1800° F. A filter enables the operator to view the part during treatment, as well as a computerized display of the temperatures, times and operating conditions…features that Rexnord manufacturing engineer Vance Bachman especially appreciates. “It’s easy for operators to understand,” Bachman says. “You can program it easily, and the operators feel comfortable working with it. Plus, it has proven very reliable and trouble-free.”