Flame Hardening Services

Flame Treating Systems, Inc. offers a variety of flame hardening services, including:

Cleaning and Servicing Flame Heads

Onsite Troubleshooting and Consulting

Developing Hardness Patterns and Flame Hardening Processes for Prototypes

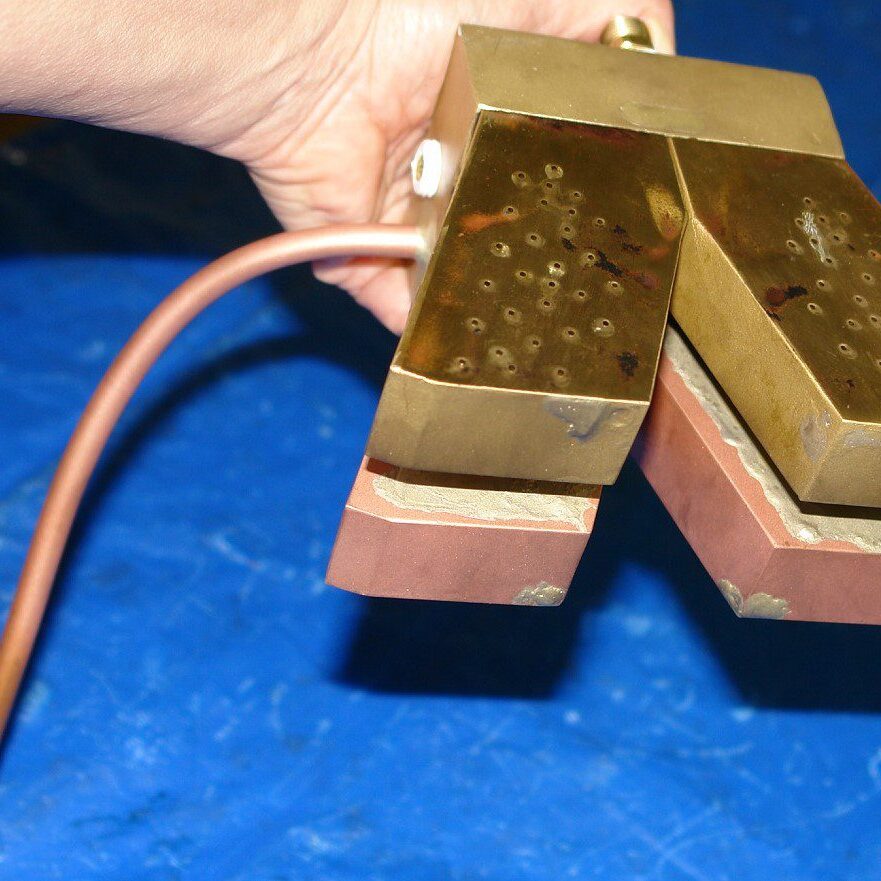

Cleaning and Servicing Flame Heads

For customers with in-house flame hardening machines, clean burning torches and flame heads are crucial to keeping production lines running smoothly. We specialize in maintaining these vital components to ensure high-quality production and extend the lifespan of your flame heads. If you’re not familiar with water-cooled flame head design, we recommend sending them to us regularly for maintenance. This ensures that the ports conduct gas, oxygen, and water cleanly with the correct pressure. We also assess and repair flame heads that no longer produce even cones or have ignition issues due to damage from burn backs. After assessing the damage, we’ll advise whether repair or replacement is the best option.

Tip: We recommend keeping spare flame heads and torch fronts in stock to avoid downtime.

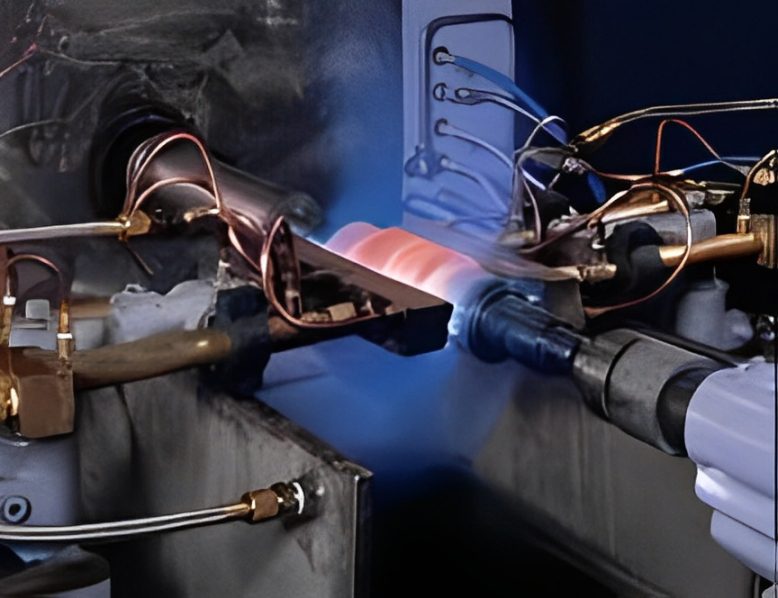

Onsite Flame Hardening Troubleshooting and Consulting

Has your flame hardening machine malfunctioned, causing production delays? If your maintenance team can't resolve the issue, give us a call. We can visit your facility to diagnose and recommend solutions. We also assist in determining whether your existing equipment can be repaired or needs to be replaced. For assistance, email mark@flametreatingsystems.com or call (919) 956-5208.

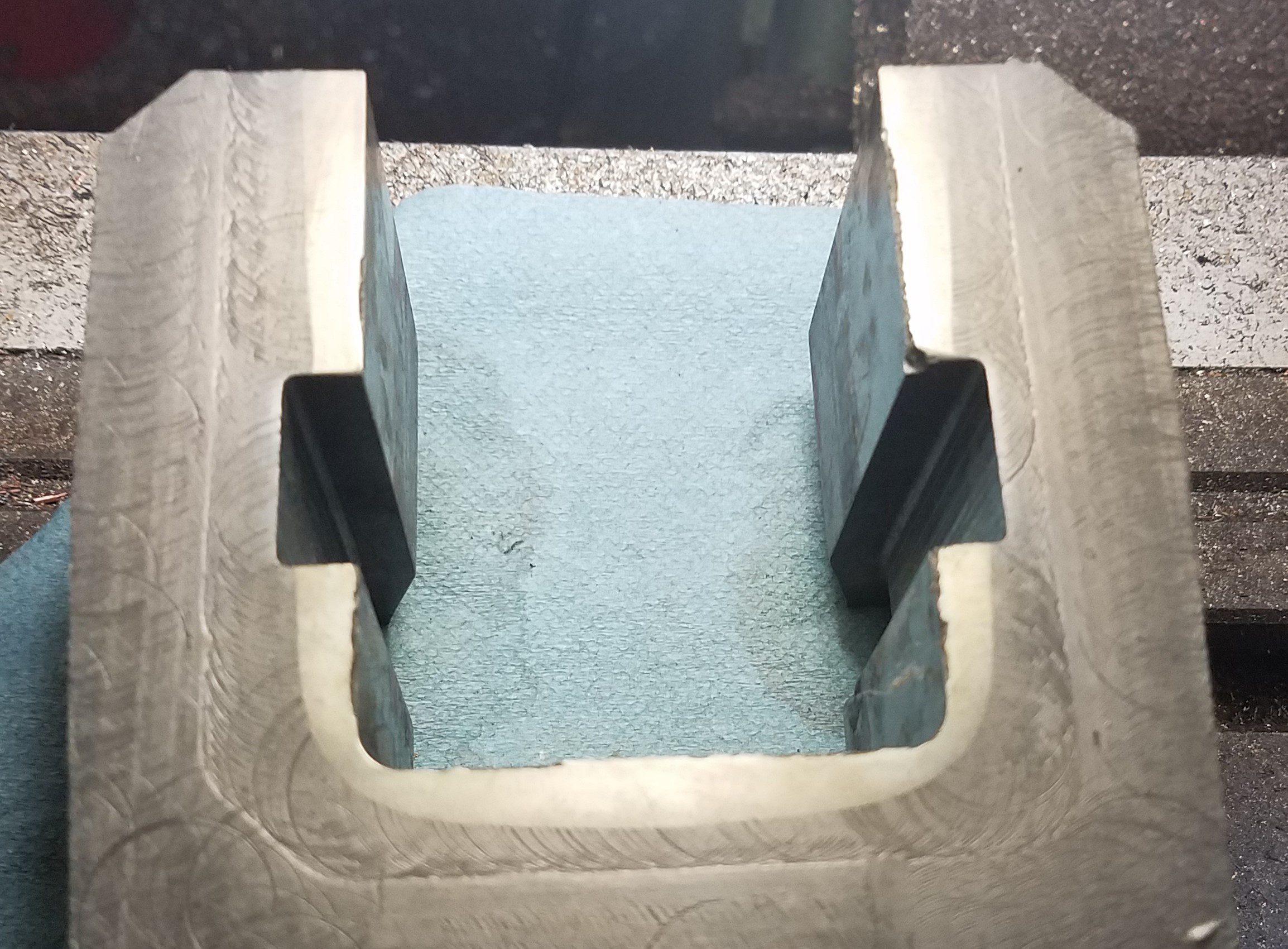

Developing Hardness Patterns and Flame Hardening Process for Prototypes

Our design team collaborates with you to develop the hardness patterns and flame hardening process for your prototype part. We'll create production-level specifications and conduct proof-of-concept hardness tests. After testing and establishing pattern parameters, we’ll document the process for reproducibility in production. For more information, email mark@flametreatingsystems.com or call (919) 956-5208.