Precision Flame Hardening Machines

100% Manufactured in the USA

Flame Treating Systems, Inc. is the world’s premier manufacturer of flame hardening machines. With over forty years of experience, we design, build, and install machines to flame harden the parts you need affordably and reliably. Our customers rely on us across four continents, and we are a small, American, family-owned business committed to making long-lasting, high-quality machines.

Our philosophy is simple: We get to know our customers and their needs so we can deliver the best equipment at the best price. We focus on low non-critical costs and high-value returns for our customers, ensuring long-term partnerships.

Built to spec. Built to last.

This version improves the structure, clarity, and flow of the text, making it easier for your readers to understand the details of each section while maintaining the technical accuracy and information.

Built to Spec. Built to Last

It all starts with your parts.

We believe that doing your own flame hardening gives you the best control over production and quality. To get a budget quote for a new flame hardening machine for your plant, we first ask you to submit the design specifications and drawings of the parts to be flame hardened. (We’ll sign any necessary non-disclosures.)

Specs should include:

The flame hardening process does not include carburizing. However, through appropriate levels of heat and quenching, the steel or iron structure reaches the desired martensite. Materials typically flame-hardened include, but are not limited to, 1045, 4140, 51200 steels, and ductile cast iron.

This initial quote gives you a budgetary number. Once the project progresses, we will work with you to specify all the details and exact costs for the new machine.

Flame Hardening Machine Applications

The following list of flame-hardening machines provides an overview of the technologies used for particular types of parts:

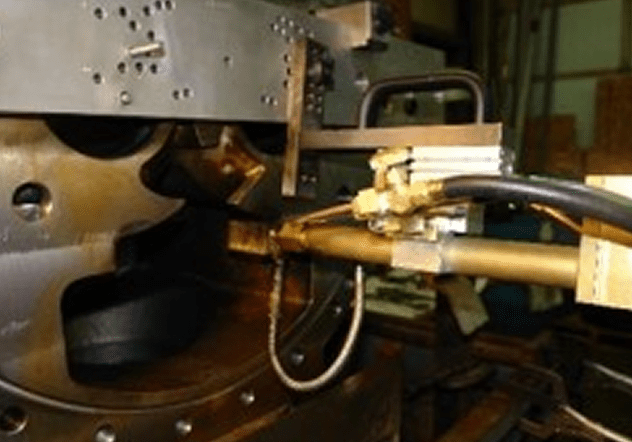

Wheels, Sprockets, Sheaves, and Gears

Flame hardening is commonly used for circular parts that undergo significant wear in heavy machinery, such as wheels, gears, and sprockets. These parts are placed on a chuck and spun in front of specially designed flame heads to produce the required pattern. The parts are then lowered into a quench that cools them at the necessary rate to achieve the desired hardness and depth.

Standard Spin Flame Hardening Machine Includes:

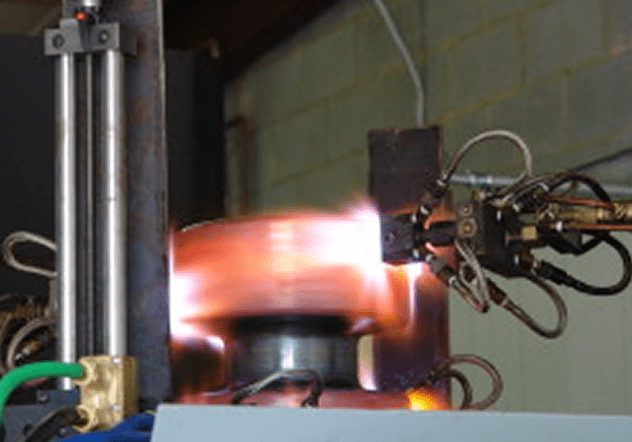

When Distortion or Pattern of Gears is a Concern

For some gears, a slower and more precise flame hardening method is needed, where one tooth is heated at a time. This method minimizes distortion by limiting the heat absorbed by the gear. It’s ideal for large gears (from a six-pitch to well below one-pitch) or for ring gears with thin rims that are prone to warping.

Tooth-at-a-Time Flame Hardening Machine Includes:

Ways and Flats

For flame-hardening flat, rectangular parts (like ways), we use a scanning or progressive method. The part remains stationary while the flame/quench head moves along the length of the part. This method can be applied to surfaces other than smooth ones as well.

Standard Progressive Flame Hardening Machine Includes:

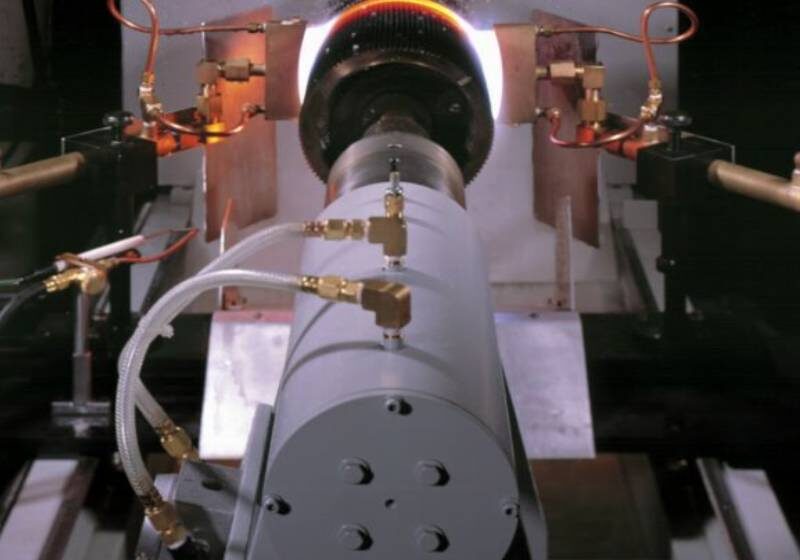

Shafts and Rolls

For shafts and rolls, both the torch and parts are spun. Water quench flame heads scan the shaft using progressive technology as it rotates on a lathe mechanism, which is called a combination flame hardening machine.

Standard Combination Flame Hardening Machine Includes:

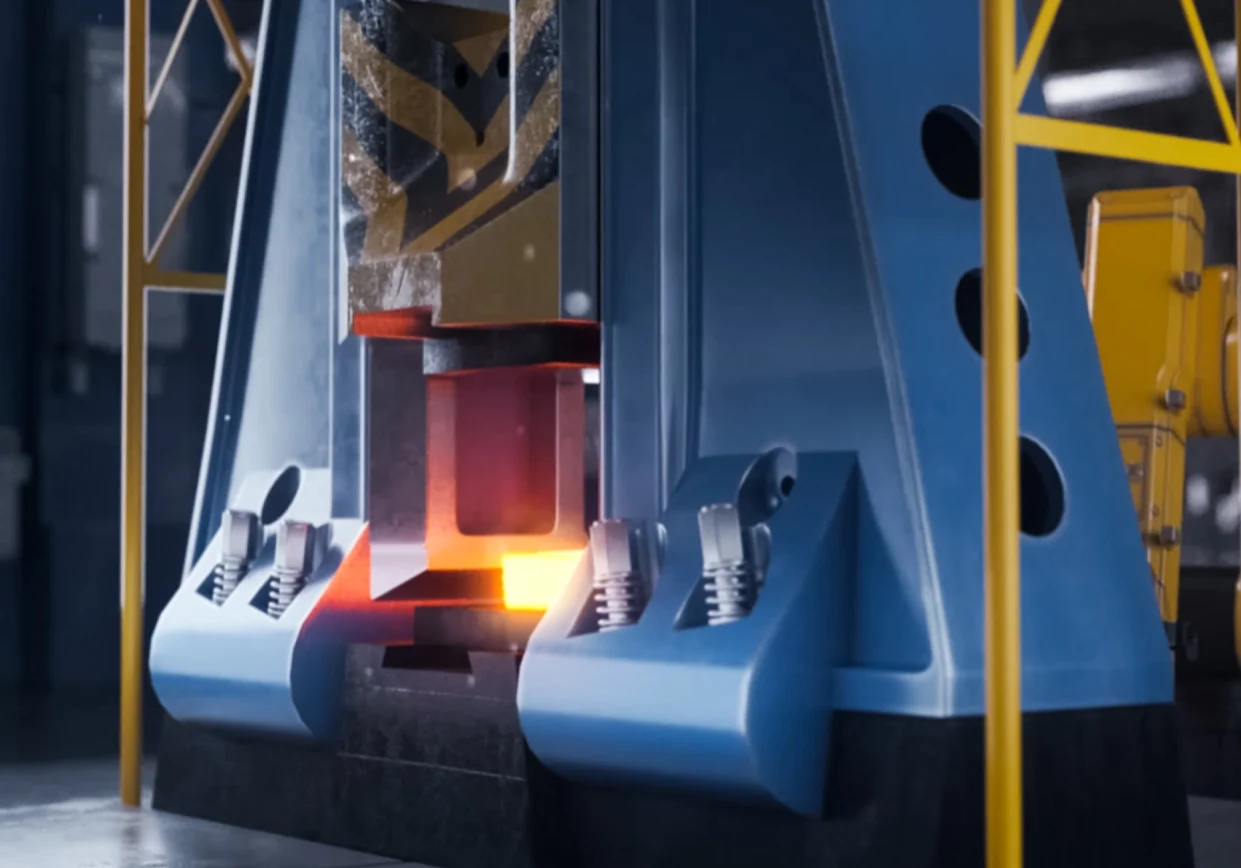

Shaft ends, Special Steel Casting Configurations, and Large Parts

For very large pieces of equipment that can’t be spun or require hardening in only a small area, we design stationary flame hardening machines. These machines heat a specific area of the part, and the part is either taken to quench or the quench is brought to the part. In these stationary machines, neither the part nor the torch moves.

Standard Stationary Flame Hardening Machine Includes:

Preparing Your Site for a New Flame Hardening Machine

While each installation is unique, here are the typical preparations you’ll need to make at your plant before we install the machine: